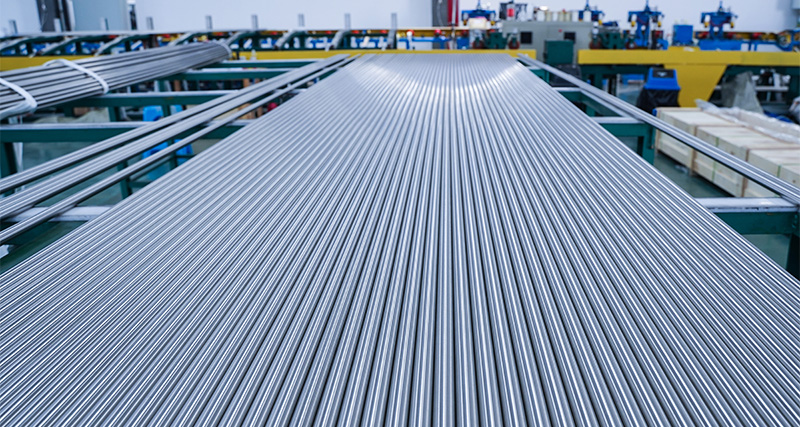

Bright Annealed(BA) Seamless Tube

Product Description

Bright annealing is an annealing process performed in a vacuum or a controlled atmosphere containing inert gases (such as hydrogen). This controlled atmosphere reduces the surface oxidation to a minimum which results in a brighter surface and a much thinner oxide layer. Pickling is not needed after bright annealing since the oxidation is minimal. Since there is no pickling, the surface is much smoother which results in better resistance to pitting corrosion.

The bright treatment maintains the smoothness of the rolled surface, and the bright surface can be obtained without post-processing. After bright annealing, the surface of the steel tube retains the original metallic luster, and a bright surface close to the mirror surface has been obtained. Under general requirements, the surface can be used directly without processing.

For bright annealing to be effective, We do the tube surfaces clean and free of foreign matter before annealing. And we keep the furnace annealing atmosphere is relatively free of oxygen (if a bright result is desired). This is accomplished by removing nearly all gas (creating a vacuum) or by displacement of oxygen and nitrogen with dry hydrogen or argon。

Vacuum bright annealing produces extremely clean tube. This tube meets the requirements for ultra high purity gas supply lines such as internal smoothness, cleanliness, improved corrosion resistance and reduced gas and particle emission from the metal.

The products are used in precision instruments, medical equipment, semiconductor industry high purity pipeline, automobile pipeline, laboratory gas pipeline, aerospace and hydrogen industry chain (low pressure, medium pressure, high pressure) Ultra high pressure (UHP) stainless steel pipe and other fields.

We also have over 100,000 meters of tube inventory, which can meet customers with urgent delivery times.

Material Grade

| UNS | ASTM | EN |

| S30400/S30403 | 304/304L | 1.4301/1.4307 |

| S31603 | 316L | 1.4404 |

| S31635 | 316Ti | 1.4571 |

| S32100 | 321 | 1.4541 |

| S34700 | 347 | 1.4550 |

| S31008 | 310S | 1.4845 |

| N08904 | 904L | 1.4539 |

| S32750 | 1.441 | |

| S31803 | 1.4462 | |

| S32205 | 1.4462 |

Specification

ASTM A213 /ASTM A269/ASTM A789/EN10216-5 TC1 or as per requirements.

Roughness & Hardness

| Production Standard | Internal Roughness | O.D Surface | Hardness max | ||

| Type 1 | Type 2 | Type 3 | Type | HRB | |

| ASTM A269 | Ra ≤ 0.35μm | Ra ≤ 0.6μm | No request | Mechanical Polish | 90 |

Process

Cold rolling / Cold drawing/ Annealing.

Packing

Each single tube capped on both ends, packed in clean single-layer of bags and final into wooden case.

Application

Chemical and petrochemical/ Power and energy/ Heat exchanger manufacturing/ Hydraulic and mechanical systems/ Clean gas transpotation

Certificate Of Honor

ISO9001/2015 Standard

ISO 45001/2018 Standard

PED Certificate

TUV Hydrogen compatibility test certificate

FAQ

- Complete Annealing.

- Isothermal Annealing.

- Incomplete Annealing.

- Spherification Annealing.

- Diffusion, or Uniform, Annealing.

- Stress Relief Annealing.

- Recrystalization Annealing.

Annealing is a heat treatment process that changes the physical and sometimes also the chemical properties of a material to increase ductility and reduce the hardness to make it more workable. The annealing process requires the material above its recrystallization temperature for a set amount of time before cooling.

Annealing is a heat treatment process used to alter the properties of metals and other materials, typically to make them softer, more ductile, and less brittle. It involves heating the material to a specific temperature and then cooling it slowly in a controlled manner, to manipulate the crystalline structure.

| No. | Size(mm) | EP Tube(316L) Size Noted by ● | |

| O.D | Thk | ||

| BA Tube Inner surface roughness Ra0.35 | |||

| 1/4″ | 6.35 | 0.89 | ● |

| 6.35 | 1.00 | ● | |

| 3/8″ | 9.53 | 0.89 | ● |

| 9.53 | 1.00 | ||

| 1/2” | 12.70 | 0.89 | |

| 12.70 | 1.00 | ||

| 12.70 | 1.24 | ● | |

| 3/4” | 19.05 | 1.65 | ● |

| 1 | 25.40 | 1.65 | ● |

| BA Tube Inner surface roughness Ra0.6 | |||

| 1/8″ | 3.175 | 0.71 | |

| 1/4″ | 6.35 | 0.89 | |

| 3/8″ | 9.53 | 0.89 | |

| 9.53 | 1.00 | ||

| 9.53 | 1.24 | ||

| 9.53 | 1.65 | ||

| 9.53 | 2.11 | ||

| 9.53 | 3.18 | ||

| 1/2″ | 12.70 | 0.89 | |

| 12.70 | 1.00 | ||

| 12.70 | 1.24 | ||

| 12.70 | 1.65 | ||

| 12.70 | 2.11 | ||

| 5/8″ | 15.88 | 1.24 | |

| 15.88 | 1.65 | ||

| 3/4″ | 19.05 | 1.24 | |

| 19.05 | 1.65 | ||

| 19.05 | 2.11 | ||

| 1″ | 25.40 | 1.24 | |

| 25.40 | 1.65 | ||

| 25.40 | 2.11 | ||

| 1-1/4″ | 31.75 | 1.65 | ● |

| 1-1/2″ | 38.10 | 1.65 | ● |

| 2″ | 50.80 | 1.65 | ● |

| 10A | 17.30 | 1.20 | ● |

| 15A | 21.70 | 1.65 | ● |

| 20A | 27.20 | 1.65 | ● |

| 25A | 34.00 | 1.65 | ● |

| 32A | 42.70 | 1.65 | ● |

| 40A | 48.60 | 1.65 | ● |

| 50A | 60.50 | 1.65 | |

| 8.00 | 1.00 | ||

| 8.00 | 1.50 | ||

| 10.00 | 1.00 | ||

| 10.00 | 1.50 | ||

| 10.00 | 2.00 | ||

| 12.00 | 1.00 | ||

| 12.00 | 1.50 | ||

| 12.00 | 2.00 | ||

| 14.00 | 1.00 | ||

| 14.00 | 1.50 | ||

| 14.00 | 2.00 | ||

| 15.00 | 1.00 | ||

| 15.00 | 1.50 | ||

| 15.00 | 2.00 | ||

| 16.00 | 1.00 | ||

| 16.00 | 1.50 | ||

| 16.00 | 2.00 | ||

| 18.00 | 1.00 | ||

| 18.00 | 1.50 | ||

| 18.00 | 2.00 | ||

| 19.00 | 1.50 | ||

| 19.00 | 2.00 | ||

| 20.00 | 1.50 | ||

| 20.00 | 2.00 | ||

| 22.00 | 1.50 | ||

| 22.00 | 2.00 | ||

| 25.00 | 2.00 | ||

| 28.00 | 1.50 | ||

| BA Tube , No request about the inner surface roughness | |||

| 1/4″ | 6.35 | 0.89 | |

| 6.35 | 1.24 | ||

| 6.35 | 1.65 | ||

| 3/8″ | 9.53 | 0.89 | |

| 9.53 | 1.24 | ||

| 9.53 | 1.65 | ||

| 9.53 | 2.11 | ||

| 1/2″ | 12.70 | 0.89 | |

| 12.70 | 1.24 | ||

| 12.70 | 1.65 | ||

| 12.70 | 2.11 | ||

| 6.00 | 1.00 | ||

| 8.00 | 1.00 | ||

| 10.00 | 1.00 | ||

| 12.00 | 1.00 | ||

| 12.00 | 1.50 | ||