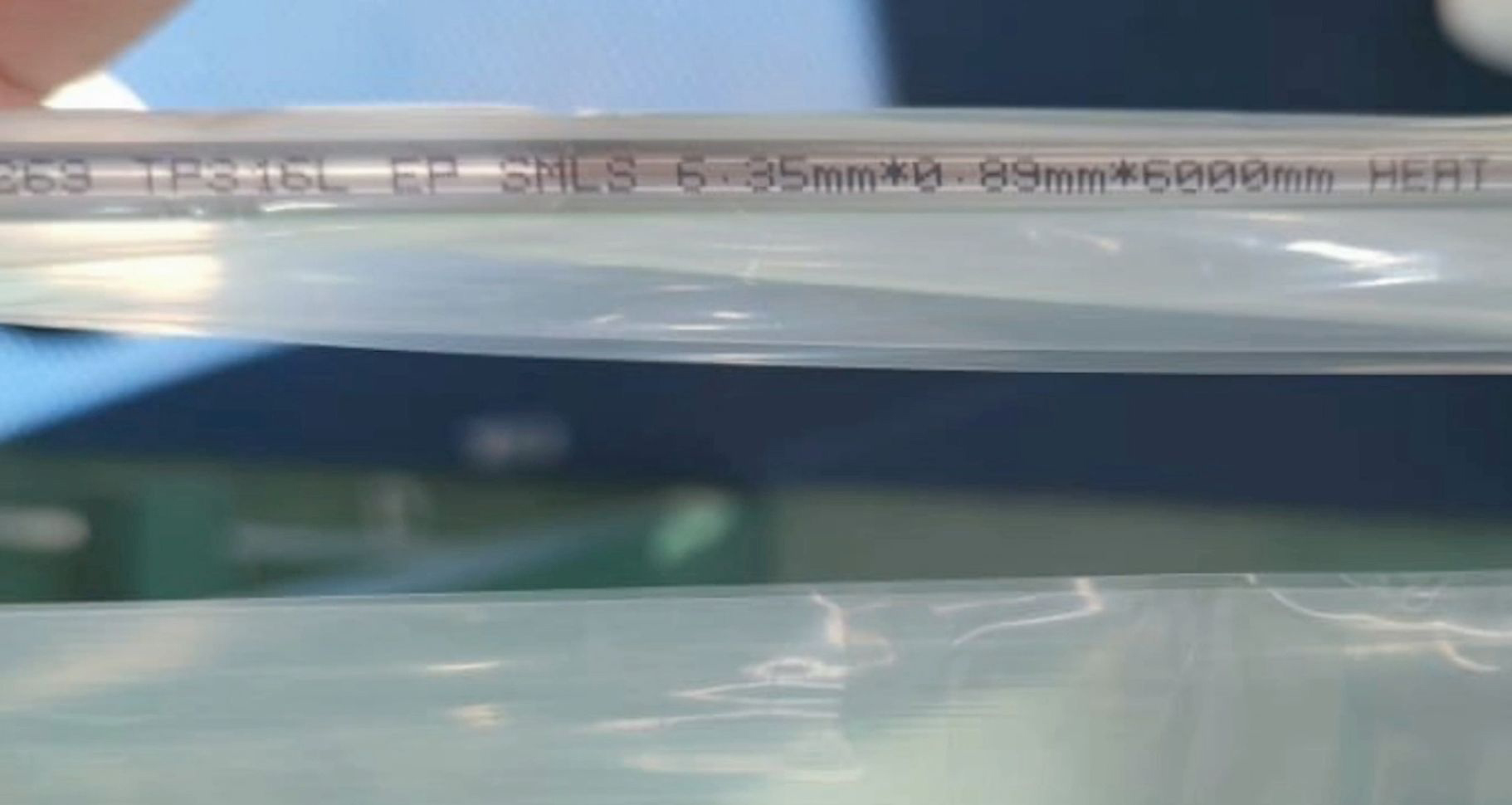

Electropolished (EP) Seamless Tube

What is Electropolishing?

Electropolishing is an electrochemical finishing process that removes a thin layer of material from a metal part, typically stainless steel or similar alloys. The process leaves a shiny, smooth, ultra-clean surface finish.

Also known as electrochemical polishing, anodic polishing or electrolytic polishing, electropolishing is especially useful for polishing and deburring parts that are fragile or have complex geometries. Electropolishing improves surface finish by reducing surface roughness by up to 50%.

Electropolishing can be thought of as reverse electroplating. Instead of adding a thin coating of positively-charged metal ions, electropolishing uses electric current to dissolve a thin layer of metal ions into an electrolyte solution.

Electropolishing of stainless steel is the most common use of electropolishing. Electropolished stainless steel has a smooth, shiny, ultra-clean finish that resists corrosion. Although nearly any metal will work, the most commonly electropolished metals are 300- and 400-series stainless steel.

The finishing of electroplating has different standards for use in different applications. These applications require medium range of finish. Electropolishing is a process through with the absolute roughness of the Electropolished Stainless Steel Pipe is reduced. This makes the pipes more accurate in dimensions and the Ep Pipe can be installed with accuracy in sensitive systems like the pharmaceutical industrial applications.

We have our own polishing equipment and produce electrolytic polishing tubes that meet the requirements of various fields under the guidance of the Korean technical team.

Our EP Tube in ISO14644-1 Class 5clean room conditions, each tube is purged with ultra high purity (UHP) nitrogen and then capped and double bagged. Certification qualifying the tubing’s production standards, chemical composition, material traceability, and maximum surface roughness is provided for all material.

Specification

ASTM A213 / ASTM A269

Roughness & Hardness

| Production Standard | Internal Roughness | External Roughness | Hardness max |

| HRB | |||

| ASTM A269 | Ra ≤ 0.25μm | Ra ≤ 0.50μm | 90 |

Relative Elemental Composition of Tube

Report 16939(1)

Process

Cold rolling / Cold drawing/ Annealing/Electropolished

Material Grade

TP316/316L

Packing

Each single tube has been purged by N2 gas, capped on both ends, packed in clean double-layer of bags and final into wooden case.

EP Tube Clean Room

Clean Room Standards: ISO14644-1 Class 5

Application

Semi-conductor/ Displays/ Food · pharmaceutical · bio production equipment/ Ultra pure clean pipeline/ Solar energy manufacturing equipment/ Shipbuilding engine pipeline / Aerospace engine / Hydraulic and mechanical systems/ Clean gas transportation

Certificate Of Honor

ISO9001/2015 Standard

ISO 45001/2018 Standard

PED Certificate

TUV Hydrogen compatibility test certificate

FAQ

Stainless Steel 316L electropolished tube is a type of stainless steel tubing that undergoes a specialized surface treatment called electropolishing (EP). Here are the key details:

- Material: It is made from 316L stainless steel, which has a lower carbon content compared to 304 stainless steel. This makes it more corrosion-resistant and suitable for applications where sensitization risks exist.

- Surface Finish: Electropolishing involves submerging the tube in an electrically charged electrolyte solution bath. This process dissolves imperfections on or just below the tube’s surface, resulting in a smooth, uniform finish. The internal surface roughness is certified to have a maximum of 10 micro-inches Ra.

- Applications:

- Pharmaceutical Industry: Used for ultra-high purity applications due to its cleanliness and corrosion resistance.

- Chemical Processing: Sample lines for detecting H2S.

- Sanitary Piping Systems: Ideal for food and beverage applications.

- Semiconductor Fabrication: Where fine smoothing of the tube is critical.

- Certifications: The governing specifications for electropolished tubing are ASTM A269, A632, and A1016. Each tube is purged with ultra-high purity nitrogen, capped, and double-bagged in ISO Class 4 clean room conditions.

Electropolished tubing offers several advantages:

- Corrosion Resistance: The electropolishing process removes surface imperfections, enhancing the material’s resistance to corrosion and pitting.

- Smooth Surface Finish: The resulting mirror-like finish reduces friction, making it easier to clean and maintain. This is crucial for applications in pharmaceuticals, food processing, and semiconductor industries.

- Improved Cleanliness: Electropolished tubes have fewer crevices and micro-roughness, minimizing the risk of bacterial growth. They are ideal for sanitary applications.

- Reduced Contaminant Adhesion: The smooth surface discourages particles and contaminants from adhering, ensuring product purity.

- Enhanced Aesthetics: The polished appearance is visually appealing and suitable for high-end applications.

Electropolished tubing is commonly used in critical environments where cleanliness, corrosion resistance, and smooth surfaces are essential.

|

No. |

Size |

|

|

O.D(mm) |

Thk(mm) |

|

|

1/4″ |

6.35 |

0.89 |

|

3/8″ |

9.53 |

0.89 |

|

1/2″ |

12.70 |

1.24 |

|

3/4″ |

19.05 |

1.65 |

|

3/4″ |

19.05 |

2.11 |

|

1″ |

25.40 |

1.65 |

|

1″ |

25.40 |

2.11 |

|

1-1/4″ |

31.75 |

1.65 |

|

1-1/2″ |

38.10 |

1.65 |

|

2″ |

50.80 |

1.65 |

|

10A |

17.30 |

1.20 |

|

15A |

21.70 |

1.65 |

|

20A |

27.20 |

1.65 |

|

25A |

34.00 |

1.65 |

|

32A |

42.70 |

1.65 |

|

40A |

48.60 |

1.65 |